Integrated Smart Factory Planning Technology

With integrating a variety of automated hardware equipment,ERP,MES,QMS,WMS and other systems,it can form a smart factory management and control platform.With integrating functions such as production scheduling,production scheduling,online quality control,workshop material planning and control,production process traceability, visual process monitoring and production status analysis and through the realization of a high degree of automation and informatization,it can create a first-class smart factory and achieve the purpose of cost reduction,production efficiency

improvement and quality assurance.

Robotic Offline Simulation Technology

By using Siemens PDPS simulation software technology, combined with secondary development of the software,and connecting the production line simulation virtual environment with PLC communi-cation through a computer, it can realize the complete electrical and robot debugging and functional verification of the production line. By simulating the real object before the manufacturing cell and the production line, and organically integrat-ing robot vision, motion trajectory, parameter control, and other technologies, it can realize the simulation operation of each process of the robot, draw the verification conclusion, and submit it to the customer for confirmation.

Robot Visual Perception Technology

By using Siemens PDPS simulation software technology, combined with secondary Combining the 3D vision technology of ROBOT Eye AI, based on DLP technology of the structured light + multi-eye vision + AI algorithm, it generates a high-resolution point cloud within 0.5 seconds. Generating the structure model of the parts to be recognized at high speed via AI algorithm, it automatically calculates the robot path generation to avoid the trajectory of the material frame and obstacles, so as to achieve the robot’s high-precision recognition of disordered parts and accurate positioning of workpiece grabbing.

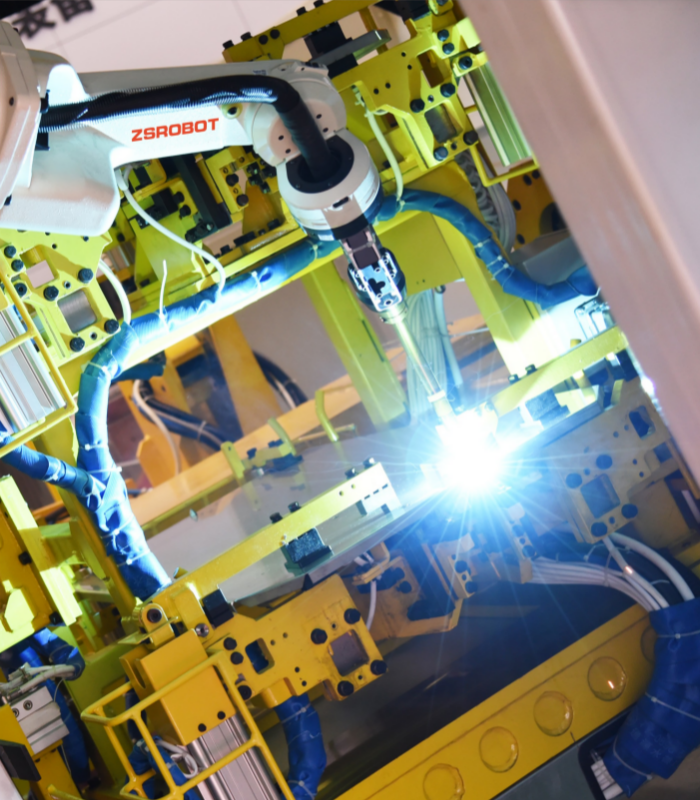

Robotic Intelligent Welding Technology

Technology of autonomous planning of welding tasks and automatic generation of motion trajectories. Technology of information sensing, modeling, and intelligent control of the welding dynamic process;

Management and control of the material flow and information flow of the welding flexible manufacturing system in smart factory, as well as the control of multiple intelligent units and complex systems involving multiple robots, sensors, and controllers.

Flexible Robotic Integration Technology

Flexible high-speed intelligent bus technology: With the comprehensive application of vision guidance, servo motion control, intelligent recognition, and through the upper control system, PLC, distributed remote I/O processing, intelligent vehicle switching device, flexible hemming, offline debugging and other technologies, it achieves flexible high-speed intelligent production and realizes unmanned production of the entire production line. This can meet the production of multiple models and realize intelligent seamless switching.

ZSROBOT Standard Product

ZSROBOT Standard Product